Orthopedic Concepts: Biomechanics of IM Nails for FRCS (Tr & Orth) Oral Examination

Biomechanics of IM Nails

EXAMINER: What is the working length of a nail?

Working length is defined as the length of a nail spanning the fracture site from its distal point of fixation in the proximal fragment to its proximal point of fixation in the distal fragment. More simply, it is the distance between the two points on either side of the fracture where the bone firmly grips the metal. Thus, working length is the unsupported portion of the nail between the two major bone fragments and reflects the length of a nail carrying the majority of the load across the fracture site.

EXAMINER: What is the relationship between the working length of a nail and bending rigidity?

The bending rigidity of a nail is inversely proportional to the square of its working length.

EXAMINER: What about torsional rigidity and working length?

Torsional rigidity is inversely proportional to a nail’s working length.

EXAMINER: What factors affect working length?

The working length of a nail can be very variable depending on:

- Type of force (bending, torsion)

- Type of fracture (fracture pattern) and if the fracture is reduced

- Interlocking

- Reaming

A nail has a shorter working length in bending with fixation of a transverse fracture than when used to stabilize a comminuted fracture.

EXAMINER: What affects bending rigidity?

Bending rigidity is affected by:

- Material properties (Young’s modulus of elasticity). A cobalt chromium nail has twice the bending stiffness as that of titanium.

- Structural properties

- Length

- Second moment area (SMA) of the nail which is a variable that describes the spatial distribution of a material within a structure. The SMA is affected by the organization and shape of the material.

For a solid circular nail, the bending rigidity is proportional to the fourth power of the nail’s radius. SMA = π.r4/4. For a hollow nail, the bending rigidity is very roughly proportional to the third power of the nail diameter.

EXAMINER: Are you sure (see above)?

It is more accurate to say the bending rigidity is directly proportional to the fourth power of the outer radius minus the fourth power of the inner radius. SMA = π. (r04 – r14)/4 where r0 is the outer radius and r1 is the inner radius.

EXAMINER: What affects torsional rigidity?

Torsional rigidity is proportional to the fourth power of the nail diameter. A sloped nail has a torsional rigidity of 1/50 that of a non-sloped nail. A nail with sharp corners or fluted edges resists torsional forces to a greater degree than a smooth-walled nail.

EXAMINER: What is the difference between second area moment and polar moment for a nail?

The second moment area and polar moment area represent the relationship between bending and torsional rigidity of a nail and its cross-sectional dimensions. The greater the material is distributed away from the neutral axis of the structure, the greater is its area and polar moment and thus the strength and rigidity against bending and torsional stress.

EXAMINER: What happens to polar moment of inertia when a nail has a slot?

The polar moment of inertia is greatly reduced.

EXAMINER: What about length of the nail, how does that affect bending rigidity?

The length of the nail between the forces working to bend it determines the length of the moment arm and therefore the magnitude of the bending moment. A similar situation applies in cases of torsional forces.

EXAMINER: How is bending and torsional stiffness related to working length?

The bending stiffness of a nail is inversely proportional to the square of its working length. The torsional stiffness is inversely proportional to its working length. The shorter the working length, the greater is the bending and torsional stiffness (rigidity) of the nail in the construct and the stronger the fixation.

EXAMINER: How does medullary reaming affect working length?

Medullary reaming prepares a uniform canal and improves nail–bone fixation towards the fracture, thus reducing the nail’s working length.

EXAMINER: What do you mean by stiffness?

Stiffness is defined as the slope of the curve in the elastic range on a force versus displacement graph.

EXAMINER: What materials are IM nails made of?

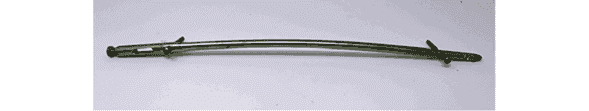

They are made of either titanium or stainless steel. IM nails can be solid or hollow.

EXAMINER: How can we reduce the stiffness of a nail?

One way of reducing stiffness is to put a longitudinal slot in the wall of a nail. This makes it much more flexible, but does so at the cost of the nail losing overall bending and torsional strength. The slot allows the cross-section to be compressed when inserted into the medullary canal. Very stiff nails may damage the bone if there is any discrepancy between the shape of the nail and that of the bone.

EXAMINER: What factors alter a nail’s axial, bending and torsional rigidity?

This can be divided into material and structural properties. Parameters include cross-sectional geometry, nail length, the presence of a longitudinal slot, and the elastic modulus of the material.