Understanding IM Nail in Orthopedics: FRCS (Tr & Orth) Oral Examination Concepts

Biomechanics of IM Nails

EXAMINER: What is the working length of a nail?

Working length is defined as the length of a nail spanning the fracture site from its distal point of fixation in the proximal fragment to its proximal point of fixation in the distal fragment. More simply, it is the distance between the two points on either side of the fracture where the bone firmly grips the metal. Thus, working length is the unsupported portion of the nail between the two major bone fragments and reflects the length of a nail carrying the majority of the load across the fracture site.

EXAMINER: How does the presence of a slot affect bending and torsional rigidity of a nail?

The presence of a slot reduces both the bending and torsional stiffness of a nail. A slot significantly affects torsional rigidity but has much less effect on bending stiffness.

EXAMINER: Why do we use sloped nails?

Apart from making a nail easier to insert, a sloped nail also reduces hoop (expansion) stresses in the bone when inserted. Hoop stresses are much higher when a solid or closed-section nail is introduced compared to a sloped nail.

EXAMINER: What is the difference between stiffness and rigidity?

While stiffness refers to a material's ability to resist deformation (force divided by displacement), rigidity is a structural property that incorporates material stiffness, geometry, and shape. Rigidity refers to a structure's ability to resist deformation and depends on both the type of material and its shape and size.

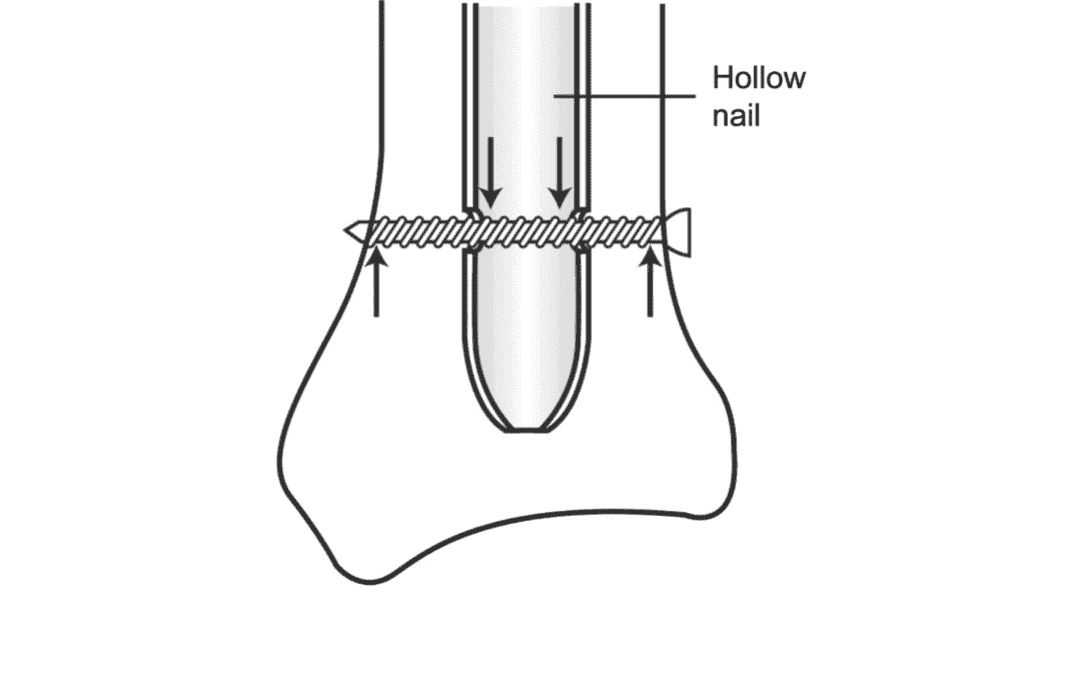

EXAMINER: Why do we use interlocking screws (bolts)? What function do they perform?

Interlocking screws help control torsion and axial loads placed on the nail and provide rotational and longitudinal stability. Historically, the use of interlocking screws expanded the indications for the use of IM nails to include more proximal, more distal, and more unstable (highly comminuted, segmental) fractures.

EXAMINER: What are the disadvantages of using interlocking screws?

Insertion requires reasonable technical skill to place. The holes in the nail act as stress risers. The weakest part of the nail to fatigue is at or just proximal to the most proximal distal locking screw. There is an increased rate of nail breakage if the fracture is within 5 cm of these screws or if the screw hole closest to the fracture is left unfilled. The closer the fracture is to the distal locking screws, the less cortical contact the nail has, which leads to increased stress on the locking screws and greater chance of screw breakage. Screw holes closer to the end of the nail allow for the fixation of more proximal or distal fractures but at the expense of stability of the construct.

EXAMINER: When nailing a long bone, how do you decide on how many locking screws to use?

The number of interlocking screws used is based on fracture location, amount of fracture comminution, and the fit of the nail within the canal. In general, one screw is sufficient for stable fractures. Midshaft transverse femoral fractures have the greatest fixation stability because of isthmic cortical contact. Oblique and comminuted fractures rely on interlocking screws for stability, as do very proximal and very distal metaphyseal fractures, where the medullary canal widens and is filled with weaker cancellous bone.

EXAMINER: How are locking screws (bolts) different from other screws used for fracture fixation?

Locking bolts have a wide core diameter and smaller outer thread diameter. The screw functions to reduce torsional stresses acting on the nail and is not designed to maximize pull-out strength.

EXAMINER: What may occur if you place too many screws in multiple planes through a nail?

Placing screws in multiple planes may lead to a reduction of fragment toggle and hinder fracture healing. An IM nail allows fracture healing with relative stability even if a nail is statically locked. Minor movements occur between the nail and screw even in a static mode of nail fixation.

EXAMINER: What effect does multiple locking screw breakage have on fracture stability?

Premature failure of locking screws, especially with unstable fracture patterns may lead to angulation, shortening, malunion, and IM nail migration.

EXAMINER: How can you reduce the risk of locking screw failure?

Compared to using a smaller screw, a larger screw diameter increases fatigue resistance. A stainless steel screw has a different fatigue life than a titanium screw (stainless steel is more ductile than titanium). Thread design and defects from the manufacturing or insertion process can also contribute to breakage. Some locking screws (bolts) may have surface defects caused by the machining of threads that could act as notches and contribute to the variability of fatigue life by a stress riser effect. Inserting a screw incorrectly can result in surface defects as well.

EXAMINER: Why not insert the largest locking bolt possible to reduce the risk of locking bolt failure?

Increasing the diameter of a locking bolt reduces the cross-section of the nail at its hole, thereby predisposing to nail failure. Nail hole size should not exceed 50% of the nail diameter. Interlocking screws undergo four-point bending loads, with higher screw stresses seen at the most distal locking sites. Under axial load, and in the absence of cortical contact, bending of the screw and screw failure may occur.