Screws: FRCS (Tr & Orth) Oral Examination Concepts

Screws: FRCS (Tr & Orth) Oral Examination Concepts

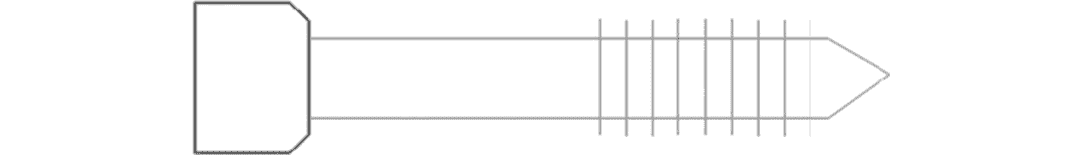

Screw Design

Screw parts and functions

EXAMINER: Can you describe the different parts of a screw and their function?

Head: Prevents the screw from sinking into the bone and provides a connection for a screwdriver. The main slot designs for a screwdriver are single slot, cruciate head, Philips, recessed hexagonal head (hex head), and Torx-6 stardriver.

Countersink: The underside of the head which is either conical or hemispherical.

Runout: The transitional area between shaft and thread, which can be a site of stress riser leading to screw breakage if the screw is inserted incorrectly.

Shaft: The smooth section between the head and thread. This is hardly present in a standard cortical screw.

Thread Geometry: Most bone screws have asymmetrical threads, i.e. flat on the upper surface and rounded underneath. This provides a wide surface for pulling and little frictional resistance on the underside.

Thread Pitch: The distance between adjacent screw threads. Coronal screws have a fine pitch, while cancellous screws have a coarse pitch.

Thread Depth: Half the difference between thread diameter and core diameter. The thread depth determines the amount of contact with bone, which in turn determines the resistance to pull-out.

Thread Shape: The shape of the thread may be V-thread, buttress thread, reverse buttress or square thread.

Lead: The linear distance travelled by a screw for one complete turn of the screw. The lead is the same as the pitch for a single-threaded screw and twice the pitch for a double-threaded screw.

Diameters:

- Core Diameter: the narrowest diameter in the thread section and is a weak part of a screw. The size of the drill bit used is equal to the core diameter. Torsional strength is proportional to the cube of the core diameter.

- Shaft Diameter: the diameter of the shaft where there is no thread.

- Outer or Thread Diameter: the maximal width of the thread. The larger the outer diameter, the greater the resistance to pull-out.

Flutes: Channels that provide a route for removal of swarf or bone debris.

Tip: The design of the tip can be non-self-tapping screw (smooth conical tip), self-tapping screw (has cutting flutes for creating its own thread/channel in cortical bone), self-drilling and self-tapping screw (will make a drill hole and cut the channel for the thread), or corkscrew tip used in cancellous screws where the tip clears the pre-drilled hole.

Screw Pull-Out Strength

EXAMINER: What do we mean by a screw's pull-out strength?

A screw's pull-out strength refers to the axial force required to remove a screw from bone.

Screw Pull-Out Strength and Biomechanics

EXAMINER: How can you maximize pull-out strength?

The pull-out strength of a screw can be increased by increasing the contact surface area between screw threads and bone, either by increasing the outer diameter, decreasing the core diameter, or increasing thread density. A fine-pitched screw with more turns engaged in a given depth of cortex can also increase pull-out strength. The use of locking screws can create a monobloc effect for greater stability.